- Feb 08, 2015 select Hole and Shaft class using radio buttons to the left and right in 'reference table window' if the tolerance does not appear in the 'reference table window'. Use filter window to make it visible; Click 'Calculate' button for results The calculator windows. Unit selection: mm or inch - All calculations are in millimeters internally.

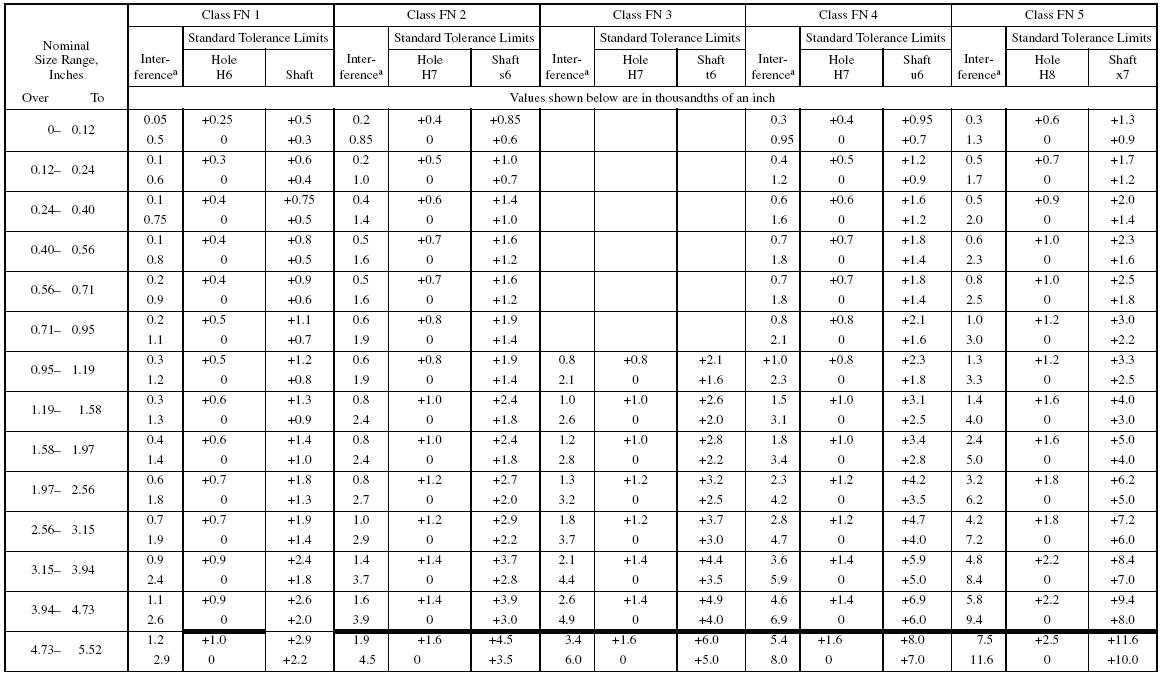

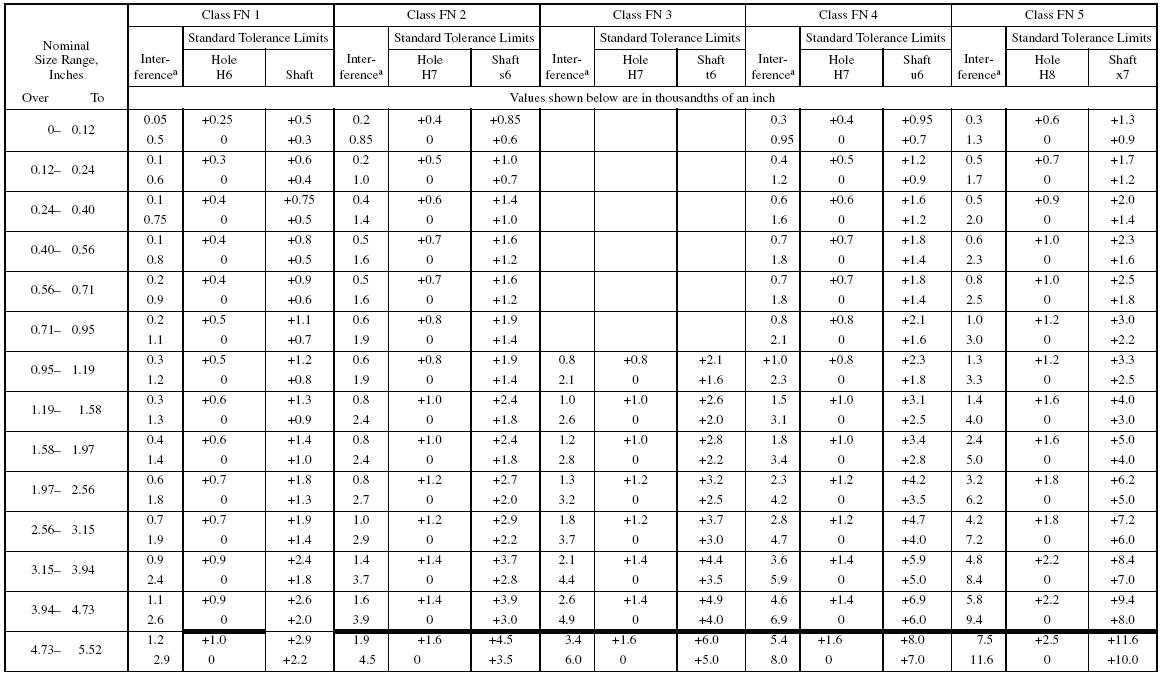

- Mechanical Tolerance Standards Charts Geometric Boundaries II GD&T Reference Book. The following links are to General Tolerance Table Charts for Standard Shaft Hole Fits per McDonald Douglas Design Guide 'Machining Tolerances'. The size ranges given are for typical size ranges utilized within industry.

The Rubber Manufacturers Association (RMA) has developed tolerance tables with ranges to provide communication between user and provider across a wide range of industries. These are helpful when designing and producing a part. You can also consult the RMA article on factors affecting tolerances of molded rubber products.

- RMA Molded Tolerances

- RMA Extrusion Tolerances

- Table 12.

Summary of RMA Drawing Designations Extruded Rubber Products - Table 13.

Standard Cross-Sectional Tolerance - Table 16.

Cut Length tolerance for unspliced extrusion - Table 18.

Spliced Length Tolerances - Table 20.

Tolerances on Internal Dimensions of Mandrel-Supported Extrusions

Metric Tolerances (mm)

Table 4-3 of Storm Drain Handbook – August 2000 Values are based on 2 inches of construction tolerance, structures with 8-inch walls and concrete pipe dimensions. Use Round Structure or Rearrange Pipes if these Angles are Exceeded. MAXIMUM ANGLE (SKEW) INTO A RECTANGULAR STRUCTURE.

| Nominal Dimension | A1 | A2 | A3 | A4 |

| above | up to and

including | Fixed | Closure | Fixed | Closure | Fixed | Closure | Fixed | Closure |

| 0 | 10 | 0.1 | 0.13 | 0.16 | 0.2 | 0.2 | 0.32 | 0.32 | 0.8 |

| 10 | 16 | 0.13 | 0.16 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.9 |

| 16 | 25 | 0.16 | 0.2 | 0.2 | 0.32 | 0.32 | 0.5 | 0.5 | 1 |

| 25 | 40 | 0.2 | 0.25 | 0.32 | 0.4 | 0.4 | 0.63 | 0.63 | 1.12 |

| 40 | 63 | 0.25 | 0.32 | 0.4 | 0.5 | 0.5 | 0.8 | 0.8 | 1.25 |

| 63 | 100 | 0.32 | 0.4 | 0.5 | 0.63 | 0.63 | 1 | 1.1 | 1.4 |

| 100 | 160 | 0.4 | 0.5 | 0.63 | 0.8 | 0.8 | 1.25 | 1.25 | 1.6 |

160 & over

(Multiply by) | x .004 | x .005 | x .005 | x .008 | x .008 | x .010 |

Inch Tolerances (in)

| Nominal Dimension | A1 | A2 | A3 | A4 |

| above | up to and

including | Fixed | Closure | Fixed | Closure | Fixed | Closure | Fixed | Closure |

| 0 | 0.40 | 0.004 | 0.005 | 0.006 | 0.008 | 0.008 | 0.013 | 0.013 | 0.032 |

| 0.40 | 0.63 | 0.005 | 0.006 | 0.008 | 0.010 | 0.010 | 0.016 | 0.016 | 0.036 |

| 0.63 | 1.00 | 0.006 | 0.006 | 0.010 | 0.013 | 0.013 | 0.020 | 0.020 | 0.040 |

| 1.00 | 1.60 | 0.008 | 0.010 | 0.013 | 0.016 | 0.016 | 0.025 | 0.025 | 0.045 |

| 1.60 | 2.50 | 0.010 | 0.013 | 0.016 | 0.020 | 0.020 | 0.032 | 0.032 | 0.050 |

| 2.50 | 4.00 | 0.013 | 0.016 | 0.020 | 0.025 | 0.025 | 0.040 | 0.040 | 0.056 |

| 4.00 | 6.30 | 0.016 | 0.020 | 0.025 | 0.032 | 0.032 | 0.050 | 0.050 | 0.063 |

6.30 & over

(Multiply by) | x .004 | x .005 | x .005 | x .008 | x .008 | x .010 |

Table 12. Summary of RMA Drawing

Designations Extruded Rubber Products

| RMA Class | Dimensional Tolerance* Table 13 | CutLength Tolerance* Table 16 | SplicedLength Tolerance* Table 16 | MandrelCured* Table 20 |

| 1 | E1 | L1 | S1 | EN1 |

| 2 | E2 | L2 | S2 | EN2 |

| 3 | E3 | L3 | S3 | EN3 |

| 4 | – | – | – | – |

Table 13. Standard Cross-Sectional Tolerance

RMA Class |

| Drawing Designation | |

| Dimensions (in Millimeters) |

| Above | Up to and including | | 0 | 1.5 | | 1.5 | 2.5 | | 2.5 | 4.0 | | 4.0 | 6.3 | | 6.3 | 10 | | 10 | 16 | | 16 | 25 | | 25 | 40 | | 40 | 63 | | 63 | 100 |

|

| | +0.15 | +0.25 | +0.40 | | 0.20 | 0.35 | 0.50 | | 0.25 | 0.40 | 0.70 | | 0.35 | 0.50 | 0.80 | | 0.40 | 0.70 | 1.00 | | 0.50 | 0.80 | 1.30 | | 0.70 | 1.00 | 1.60 | | 0.80 | 1.30 | 2.00 | | 1.00 | 1.60 | 2.50 | | 1.30 | 2.00 | 3.20 |

|

RMA Class |

| Drawing Designation | |

| Dimensions (in Inches) |

| Above | Up to and including | | 0 | 0.06 | | 0.06 | 0.10 | | 0.10 | 0.16 | | 0.16 | 0.25 | | 0.25 | 0.39 | | 0.39 | 0.63 | | 0.63 | 0.98 | | 0.98 | 1.57 | | 1.57 | 2.48 | | 2.48 | 3.94 |

| | +0.006 | +0.010 | +0.015 | | 0.008 | 0.014 | 0.020 | | 0.010 | 0.016 | 0.027 | | 0.014 | 0.020 | 0.031 | | 0.016 | 0.027 | 0.039 | | 0.020 | 0.031 | 0.051 | | 0.027 | 0.039 | 0.063 | | 0.031 | 0.051 | 0.079 | | 0.039 | 0.063 | 0.098 | | 0.051 | 0.079 | 0.126 |

|

Table 16. Cut Length tolerance for unspliced extrusion

RMA Class |

| Drawing Designation. | |

| Length (in Millimeters) |

| Above | Up to and including | | 0 | 40 | | 40 | 63 | | 63 | 100 | | 100 | 160 | | 160 | 250 | | 250 | 400 | | 400 | 630 | | 630 | 1000 | | 1000 | 1600 | | 1600 | 2500 | | 2500 | 4000 | | 4000 |

| | +0.7 | +0.04 | +1.6 | | 0.08 | 1.3 | 2.0 | | 1.0 | 1.6 | 2.5 | | 1.3 | 2.0 | 3.2 | | 1.6 | 2.5 | 4.0 | | 2.0 | 3.2 | 5.0 | | 2.5 | 4.0 | 6.3 | | 3.2 | 5.0 | 10.0 | | 4.0 | 6.3 | 12.5 | | 5.0 | 10.0 | 16.0 | | 6.3 | 12.5 | 20.0 | | 0.16% | 0.32% | 0.50% |

|

| Length (in Inches) |

| Above | Up to and including | | 0 | 1.6 | | 1.6 | 2.5 | | 2.5 | 4.0 | | 4.0 | 6.3 | | 6.3 | 10.0 | | 10.0 | 16.0 | | 16.0 | 25.0 | | 25.0 | 40.0 | | 40.0 | 63.0 | | 63.0 | 100.0 | | 100.0 | 160.0 | | 160.0 |

| | +0.03 | +0.04 | +0.06 | | 0.03 | 0.05 | 0.08 | | 0.04 | 0.06 | 0.10 | | 0.05 | 0.08 | 0.13 | | 0.06 | 0.10 | 0.16 | | 0.8 | 0.13 | 0.20 | | 0.10 | 0.16 | 0.25 | | 0.13 | 0.20 | 0.40 | | 0.16 | 0.25 | 0.50 | | 0.20 | 0.40 | 0.63 | | 0.25 | 0.50 | 0.80 | | 0.16% | 0.32% | 0.50% |

|

Table 18. Spliced Length Tolerances

RMA

Class |

| Drawing Designation | |

| Millimeters |

| Above | Up to and including | | 0 | 250 | | 250 | 400 | | 400 | 630 | | 630 | 1000 | | 1000 | 1600 | | 1600 | 2500 | | 2500 | over |

| | +302 | +3.2 | +7.1 | | 4.0 | 7.1 | 8.0 | | 5.0 | 8.0 | 9.0 | | 6.3 | 9.0 | 10.0 | | 8.0 | 10.0 | 11.2 | | 10.0 | 11.2 | 12.3 | | 012.5 | 12.5 | 16.0 |

|

| Inches |

| Above | Up to and including | | 0 | 10 | | 10 | 16 | | 16 | 25 | | 25 | 40 | | 40 | 63 | | 63 | 100 | | 100 | over |

| | +.13 | +.25 | +.28 | | .16 | .28 | .32 | | .20 | .32 | .36 | | .25 | .36 | .40 | | .32 | .40 | .45 | | .40 | .45 | .50 | | .50 | .50 | .53 |

|

Table 20. Tolerances on Internal Dimensions

of Mandrel-Supported Extrusions

RMA

Class |

| Drawing Designation | |

Nominal Dimensions

(in Millimeters) |

| Above | Up to and including | | 0 | 4 | | 4 | 6.3 | | 6.3 | 10 | | 10 | 16 | | 16 | 25 | | 25 | 40 | | 40 | 63 | | 63 | 100 | | 100 | 160 | | 160 |

| | +0.20 | +0.20 | +0.35 | | 0.20 | 0.25 | 0.40 | | 0.25 | 0.35 | 0.50 | | 0.35 | 0.40 | 0.70 | | 0.40 | 0.50 | 0.80 | | 0.50 | 0.70 | 1.00 | | 0.70 | 0.80 | 1.30 | | 0.80 | 1.00 | 1.60 | | 1.00 | 1.30 | 2.00 | | 0.6% | 0.8% | 1.2% |

|

Nominal Dimensions

(in Inches) |

| Above | Up to and including | | 0 | 0.16 | | 0.16 | 0.25 | | 0.25 | 0.40 | | 0.40 | 0.63 | | 0.63 | 1.00 | | 1.00 | 1.60 | | 1.60 | 2.50 | | 2.50 | 4.00 | | 4.00 | 6.30 | | 6.30 |

| | +0.008 | +0.08 | +0.014 | | 0.008 | 0.010 | 0.016 | | 0.010 | 0.014 | 0.020 | | 0.014 | 0.016 | 0.028 | | 0.016 | 0.020 | 0.032 | | 0.020 | 0.028 | 0.040 | | 0.028 | 0.032 | 0.051 | | 0.032 | 0.040 | 0.063 | | 0.040 | 0.051 | 0.079 | | 0.6% | 0.8% | 1.2% |

|

Don't miss anything! Subscribe to our newsletter.

Get the latest articles, reports and industry news.

YOU MIGHT ALSO LIKE

6 Reasons to Use Custom Rubber Parts in the Glass and Glazing Industry

Architects and engineers are constantly pushing the limits of what architectural glass and glazing systems can do.

More details

Rubber extrusions sample kit

Tolerance Table In Inches

A selection of commonly used rubber materials and custom extruded shapes we manufacture for commercial glazing, medical, food and beverage, and HVAC applications. See, touch and feel silicone and EPDM swatches of various colors, hardness’s and specifications as well as extruded samples.

More details

7 MISTAKES TO AVOID WHEN DESIGNING RUBBER EXTRUSIONS

Tolerance Table In Inch Size

Whether launching a new product line, improving an existing product’s performance or reducing manufacturing costs, manufacturers of curtain walls and architectural glass and glazing go to great lengths to create new or improved extrusion designs.

More details

Plain washers are made of ferrous or non-ferrous metal, plastic or other material as specified. The tolerances indicated in the tables are intended for metal washers only.

American National Standard Type A Plain Washers - Preferred Sizes ANSI/ASME B18.22.1-1965 (R1998)

a Nominal washer sizes are intended for use with comparable nominal screw or bolt sizes.

b the 0.734-inch, 1.156-inch, and 1.469-inch outside diameters avoid washers which could be used in coin operated devices.

All dimensions are in inches.

Designation 'N' (narrow) and the Standard Plate 'W' (wide), these sizes as well as all other sizes of Type A Plain Washers are generally specified by ID, OD, and Thickness dimensions.

Location Tolerances: Inside and outside diameters shall be concentric to within the specified inside diameter tolerance.

© Copyright 2000 - 2021, by Engineers Edge, LLC www.engineersedge.com

All rights reserved

Disclaimer | Feedback

Advertising | Contact | Privacy Policy

Tolerance Table In Inch Conversion

Date/Time: